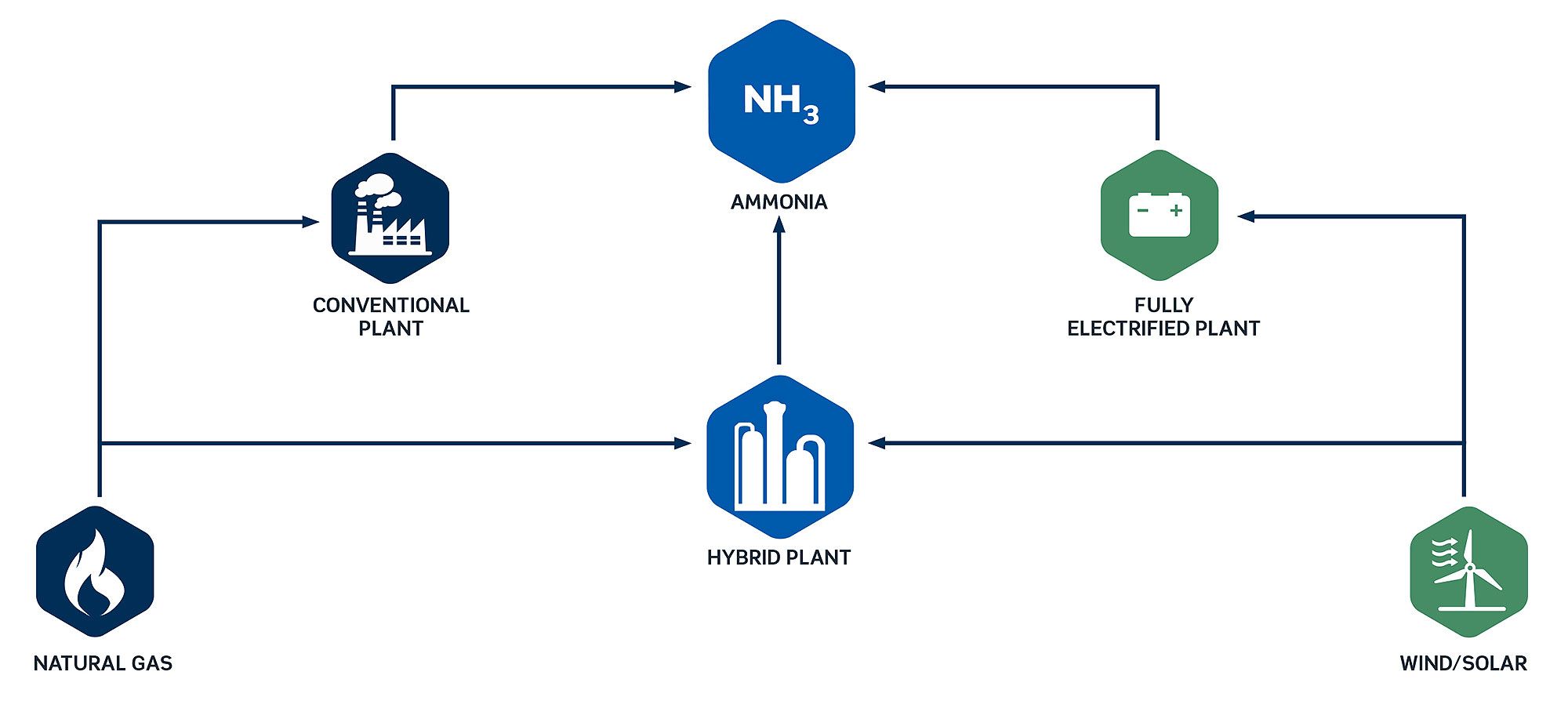

Producers aiming for a gradual, cost-effective reduction in their ammonia operation’s carbon footprint - without a corresponding decrease in yield - can leverage a combination of new and established Topsoe technologies to realize their decarbonization goals, and begin their transition into the renewable future.

By combining our efficient SOEC high-temperature electrolysis technology with patented technologies from the DynAmmo™ ammonia-production process, we provide a full-spectrum solution for comprehensive front- and back-end industrial success. A reduction in levelized cost is facilitated through SOEC’s smart integration with waste-heat sources – which reduces electrical power requirements associated with conventional electrolysis technology – as well as the ability to safely adjust operation across a variety of input conditions and power fluctuations with a highly responsive DynAmmo™ setup.

With this hybrid green-ammonia revamp, operators can optimize usage of natural gas and electricity while directly reducing, and ultimately eliminating, their carbon intensity per ton of ammonia.

Scalable decarbonization with SOEC electrolysis

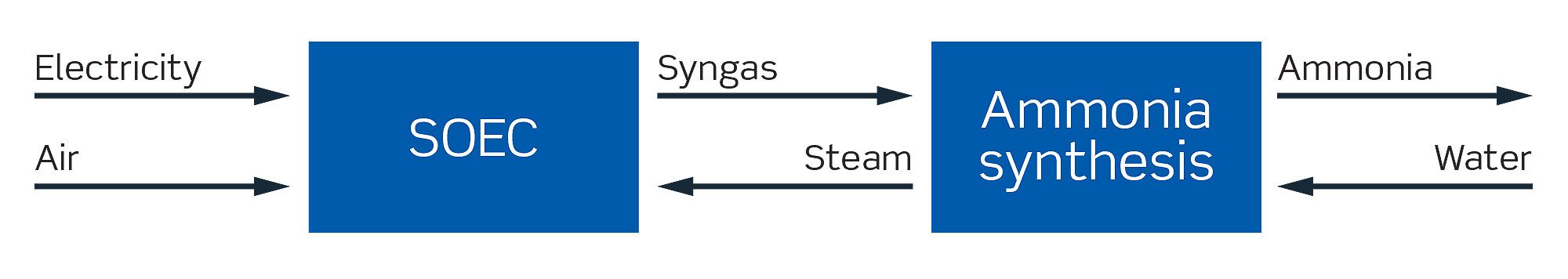

In addition to our comprehensive ammonia knowledge, our hybrid green-ammonia system employs a market-leading proprietary solution for high-temperature, high-efficiency electrolysis: the Topsoe SOEC cell. This groundbreaking technology is uniquely suited to industrial settings where significant waste heat, generated by the exothermic ammonia-synthesis reaction, is readily available. It is ideal for use by an integrated high-temperature process, significantly lowering the amount of energy required for ammonia production.

Synergy between SOEC technology and the ammonia-synthesis system optimizes the energy efficiency of your green-ammonia production.

Synergy between SOEC technology and the ammonia-synthesis system optimizes the energy efficiency of your green-ammonia production.

Unbeatable ammonia performance

A hybrid green-ammonia operation’s CAPEX and OPEX derives from the price of electrical power, electrolyzers, and “flexibility levers,” which include the minimum ammonia-loop process load and its ramping rate. DynAmmo™ enables greater loop flexibility throughout the operational cycle, allowing a process ramp from 10% to 100%, or 100% to 10%, in a span of mere minutes, resulting in several key benefits.

Superior catalysts for reliably superlative performance and insight

As the global market leader in ammonia-synthesis catalysts, our high-performance offerings form the center of successful green ammonia operations, around which your entire plant is engineered and by which your levelized cost of ammonia is minimized.

Our unmatched knowledge of ammonia catalyst kinetics helps us design your plant for maximum longevity, cost-efficiency, and operational flexibility while utilizing intermittent renewable power, ensuring that your green-ammonia operation enjoys maximum de-risking while meeting its business targets.

One-Stop-Shop for Navigating Energy Transition Journey

Green hydrogen, green ammonia, and green methanol represent the foremost components of the global energy transition, and Topsoe is the sole global licensor and leader active within each of their industries.

Our expertise in harnessing both the technological and scientific processes behind green chemical and fuel production is complemented perfectly by our ability to manufacture all of our ammonia catalysts in-house, and by our new SOEC solution.

Working with Topsoe as your one-stop partner allows you to: